PE PRODUCTS

PE LINERS & Shrink Films & Pallet Hoods

BIG BAGS & LINERS

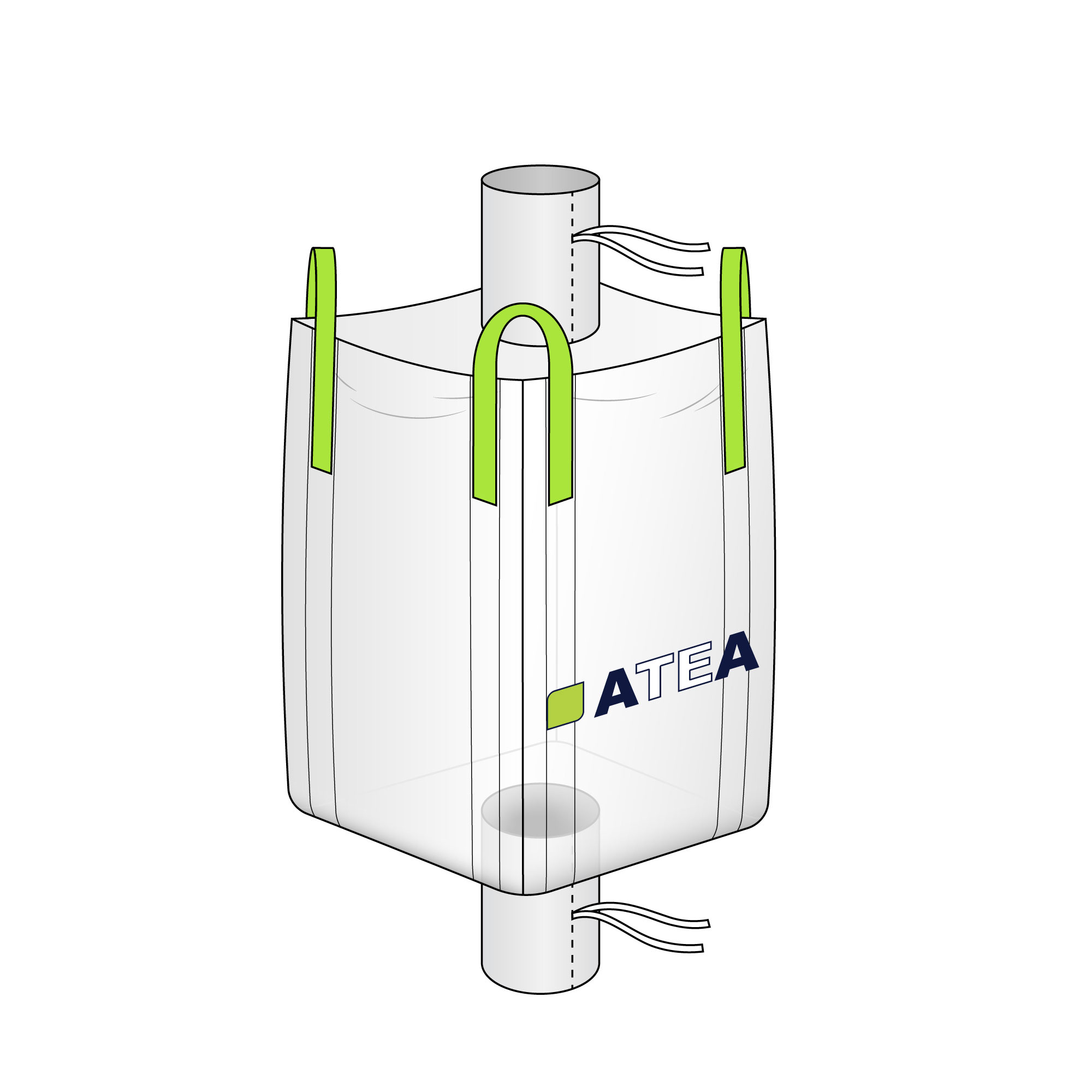

Big bags with inliner provide a suitable solution for materials that require a high degree of purity when packed.

The inliner covers the whole inner side of the big bags so the material does not come into contact with the fabric or seams. For very tiny powdery materials dustproof seams are usually not enough. In these cases inliners are used to prevent leakage and provide barrier property to the big bag.

FIBC bulk bag liners are required for certain products and applications. Liners serve multiple purposes including, but not limited to:

LINER TYPES

Standard Liners

Standard liners are like a PE hose covering the interior surfaces of the big bags , but they have some wrinkles to adjust to the big bag shape which may slow down product flow.

Formliner

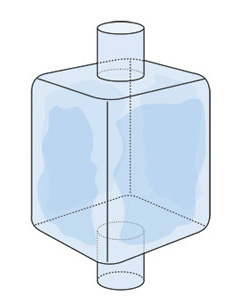

Formliners are Inliners in the shape of a bottle which adjust to the form of the big bag at the spouts. This allows a smooth material flow within the jumbo bag and also provides easier spout handling during the filling operation.

Q-Liner / Gambo Liner / Baffle liner

Q-liners have baffles from PE inside the liner, which makes the big bag with inliner also a Q-bag at the same time. This is a very cost intensive premium big bag solution.

Suspended inliner

Special type for one and two loop bags

Open top

Open top with gussets

Bottle shaped top

Bottle shaped top and bottom

Bottle shaped and sewn-in

Suspended

Liner Materials

The markings must be within a rectangular border with a vertical line separating the IPPC logo (on the left) from the identifying data. The border lines may be solid or broken; and the corners may be rounded.

- PE Blend: The most common and standard liner material. Usually made from LDPE . Available in conductive and antistatic versions. Normally transparent but other colors are also possible such as white , blue and black.

-

Aluminum Foil: High barrier property film available in most shapes. Form shaped aluminum liners, improve filling, discharging, handling and stability of the outside of the bag. Foil liners offer great moisture, oxygen, and UV protection and are compatible with a wide variety of bulk bags.

Very high gas and aroma barrier.

High heat resistance. -

EVOH Films: High barrier property film available in most shapes.

Very high gas and aroma barrier

High sealing capacity

High mechanical strength

High puncture resistance

High heat resistance -

PA Films: High barrier property film available in most shapes , especially used for EPS.

High gas, moisture and aroma barrier

High sealing capacity

High mechanical strength

High heat resistance

High corrosion and impact resistance

EVOH

EVOH formula:

EVOH Oxygen Barrier

Oxygen transmission rate of films:

Gas Barrier Property

| Material | cm3, 20μ/m²,day,atm @20°C, 65%RH |

|---|---|

| 32 mol% Et. EVOH | 0.4 |

| 38 mol% Et. EVOH | 0.7 |

| PVdC(Polyvinylidene chloride) | 2.6 |

| Polyamide(Nylon) | 38 |

| PET(Polyester) | 54 |

| HDPE(Hight Density Polyethylene) | 2300 |

| PP (Polypropylene) | 3000 |

| PC (Polycarbonate) | 5000 |

| PS (Polystyrene) | 8000 |

| LDPE (Low Density Polyethylene) | 10000 |

| EVA (Ethylene Vinyl Acetate) | 18000 |

ALU – EVOH – PA

ALU – EVOH – PA liners are known as barrier liners, their main functions are as follows;

- Moisture and oxygen sensitive products storage

- Air, humidity and gas control

- Storage of products with a long shelf life

- Food and pharma products storage

- Storage of materials that need to be protected from external factors

- Storage of products that should not lose their special odor, gas, heat balance and aroma

- Please contact an ATEA expert for more details about liners.

BIG BAG LINER INSERTION OPTIONS

• Loose Inserted inliner : The inliner is simply put inside the big bag without attaching it to the body of the big bag. Preblowing recommended. Loose inserted inliners are mostly used for simple big bags and chosen by customers due to their cost-efficiency.

• Tabbed inliner : The liner is fixed with eight tabbings in the eight corners of the big bag. This prevents efficiently the movement of the liner within the jumbo bag which may otherwise create problems during filling and discharging.

• Sewn-in inliner :Inliner is fixed in the FIBC by sewing along the entire length of the big bag in all four side seams. Inliners that are sewn along the entire length are stronger fixed inside the FIBC than those that are fixed with tabbings. A movement of the liner is efficiently prevented.

• Glued inliner : The inliner is fixed to the walls of the big bag by hotmelt glue. This is an expensive option that provides the firmest attaching. ATEA’s recommendation.

No Attaching

Attaching With Tabs

Attaching With Flangers

Attaching With Glue

Dimensions of PE inliners are usually determined based on the dimensions of a big bag for which it is used.

Depending on the type and purpose of the material, the thickness of the inliner can vary between 50 -200 microns (my), usually it is 70-80 my for most FIBCs.

For type B and type C big bags, there is a special type of inliner that is electro-conductive.

For big bags with one and two loops almost always a inliner is used. These inliners have a special shape (See suspended inliner).

Inliner can meet the needs for big bags in the food industry. FIBC can be made with special measures for cleanliness.

COMMON USES OF LINERS

#1 Fine Powders

Flexible Intermediate Bulk Containers with coating or sift proof seams work well for a variety of powdered products. But when sift proofing is not enough to keep a fine powder from leaking through the sew lines, a polyethylene liner can be a great solution. Liners can be purchased separately and manually inserted into the bag, or manufactured with the liner already inserted to make the packing process more efficient. Liners also provide a moisture barrier keeping moisture in as well as keeping moisture out – which can be extremely important when working with fine powders.

#2: Food Grade Products

FIBCs are becoming increasingly popular for packing food or food related products. If the product being packed is an powdered, granular, or dry flow-able form, food grade liners can help keep product fresh and free from contamination. If the food product is in powdered form, liners can help with discharge of product so the end user gets all contents out of the bag.

#3: Pharmaceutical Products

Pharmaceutical products are often held to the same, if not more, stringent standards as food grade products and often require liners. Additionally, many pharmaceutical products are sensitive to elements such as moisture and UV rays making liners essential when transporting these materials.

#4: Over the Bag

Liners are commonly used inside bulk bags, but there are many applications where it makes sense to use polyethylene liners over the bag. An overbag liner is put under the bag before it is filled. After the bag has been filled, the poly liner is pulled over the bag and tied. When used properly, the overbag can serve as an extra barrier when product is shipped.

PALLET HOODS & SHRINK FILMS

ATEA PRODUCES

PALLET HOODS

“ATEA” pallet covers are made from polyethylene and polypropylene. They can be perfectly adapted to the volume of your pallet and be customized with your companies’ logo to enhance the awareness of your products in the market.

This cover protects your palettes from the elements.

Heat-shrinkable covers are available, allowing you to bind you bags or packages more tightly.

Large format hoods can be supplied a range of colours and thicknesses to meet specific customer specifications.

We can supply pallet hoods for automatic and manual applications to suit every application. Plastic polythene covers and hoods, wrap around pallets to secure cargo and protect goods from weather.

USES & FUNCTIONS OF PALLET HOODS

A PE hood is fed over the top of the pallet to protect the goods that are on the pallet.

“ATEA” offers a wide range of products to meet your requirements.

The “ATEA” PE hood protects and provides stability for your packaged products.

PE hoods can be used to protect big bags, especially for storage outdoors.

The PE hood also works as an extra protection against UV radiation, rain and snow.

A PE film with excellent strength. “ATEA”s Pallet Cover Film comes with UV resistance for long term exposure to the sun.

FEATURES & BENEFITS:

- UV resistant

- Colours: transparent / wide range of colors / printed 3

- Width: up to 220 cm

- Thickness: from 70 to 120 cm

- Easy to use

- Available in rolls with internal diameter 76 or 152mm and also in pieces.

- Ideal for outdoor storage

- APPLICATIONS:

- Covers all types of pallets, keeping them clean, stable and dry.

SHRINK FILMS

Shrink film that offers superb performance in holding and protecting products and objects during handling and transport. “ATEA” product line includes standard and high quality shrink films are determined by your requirements.

We offer printing with 8-color, high quality and choice, including UV and color. Shrink film is a well established and cost-effective method for collecting cans, bottles, cartons and pallets and fix the goods during transport to the benefit of low weight.

In addition, the shrink film is suitable for recycling and incineration. Shrink film, with the use of heat (oven or flame), shrinks and forms to whatever structure is underneath it. The film shrinks in both directions depending on the goods to be packed.

A PE thermal shrink wrap film with excellent strength and elasticity. “ATEA” Shrink Film comes with UV resistance for long term exposure to the sun.

USES & FUNCTIONS OF SHRINK FILMS

Shrink film is commonly used as an overwrap on many types of packaging, including boxes, cartons and pallets

FEATURES & BENEFITS:

- When heat is applied, it shrinks tightly over whatever it is covering.

- UV resistant

- Colours: transparent / wide range of colors / printed

- Width: from 50 up to 100 cm

- Thickness: from 60 up to 100 cm

- Easy to use

- Available in rolls with internal diameter 76 or 152mm.

- Flexiable storage

- Heat resistant

- Protects from humidity ,dust and dirty

- APPLICATIONS:

- Packages / covers plenty of products keeping them clean and stable.